Manufacturers

I am aware of three companies manufacturing compatible motors. All appear to produce a good-quality product.

Switec

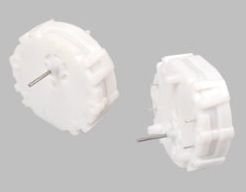

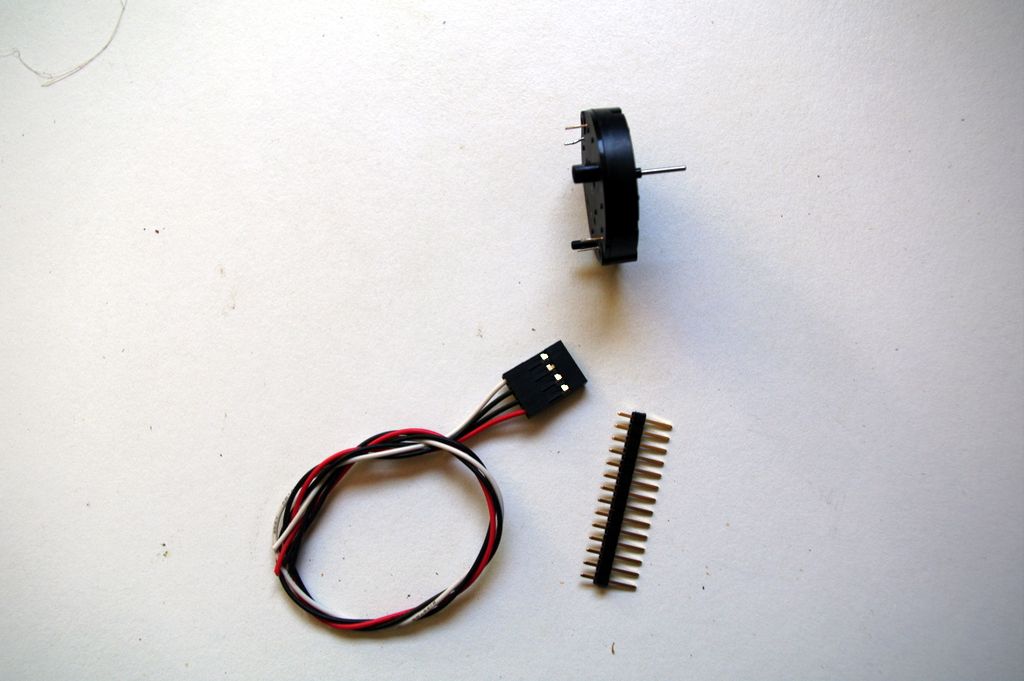

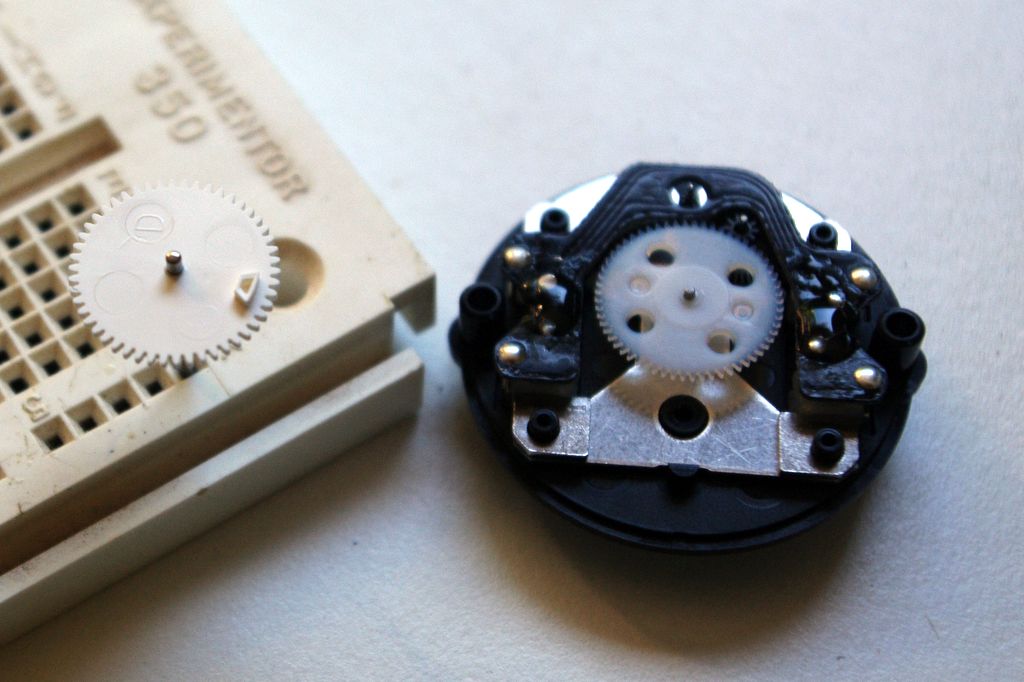

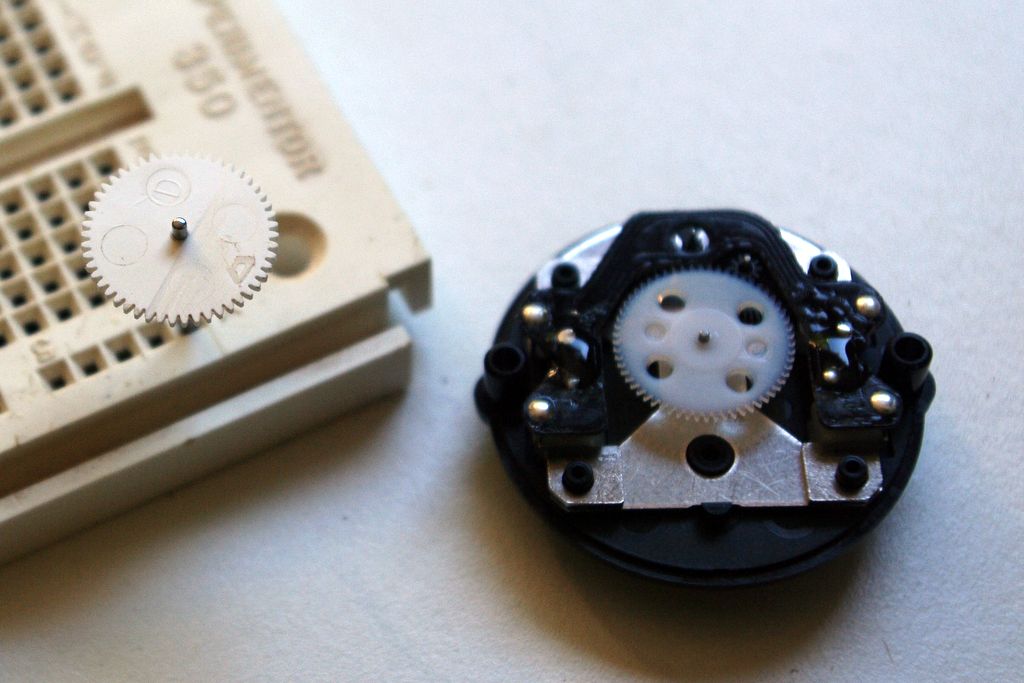

Switec was originally the technology arm of the Swiss watch company Swatch. The stepper business was sold off to Singapore-based Juken Technology in 2009. Switec motors are white, and have part numbers starting with “X”.

VID

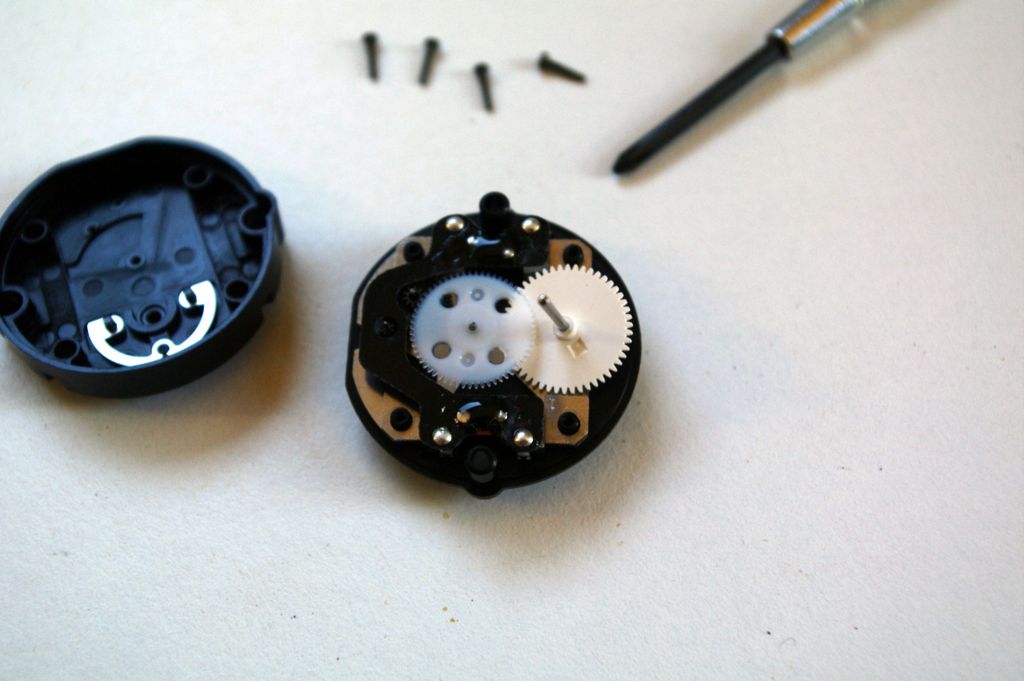

Hong Kong based VID also manufacture a range of similar motors. Their motors are black, and have a black model number starting with “vid”.

MCR

Chinese company MCR Motor manufacture a range of compatible motors. Their motors are white. with part numbers starting with “MR”.

X25 Product Numbers

Each manufacturer produces a number of variations of the motor.

| Switec | VID | MCR | Contacts | Mounting Pegs | Internal Stop | Shaft |

|---|---|---|---|---|---|---|

| X25.156 | rear | no | no | standard | ||

| X25.166 | rear | no | yes | standard | ||

| X25.158 | rear | rear | no | standard | ||

| X25.168 | VID29-02 | MR1108 | rear | rear | yes | standard |

| X25.278 | rear | rear | no | long (+2mm) | ||

| X25.288 | VID29-04 | rear | rear | yes | long (+2mm) | |

| X25.559 | front | front | no | standard | ||

| X25.569 | VID29-05 | MR1107 | front | front | yes | standard |

| X25.579 | front | front | no | long (+2mm) | ||

| X25.589 | VID29-07 | front | front | yes | long (+2mm) | |

| X25.679 | front | front | no | long (+2mm) | ||

| X25.689 | front | front | yes | long (+2mm) |

Other Switec Series

X23 Series

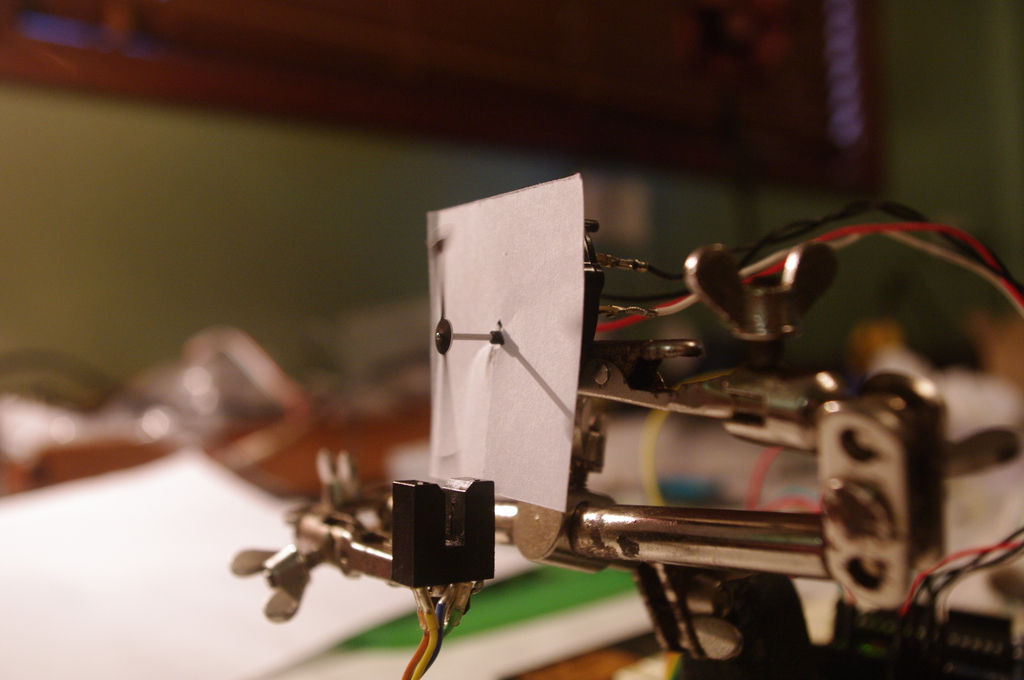

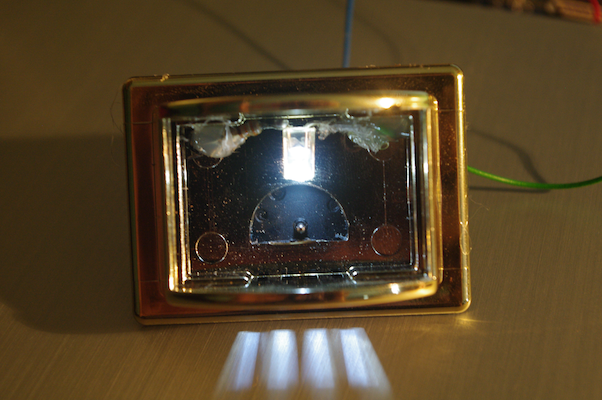

The X23 motors have an a hollow metal shaft encasing a transparent light guide to make it possible to have an illuminated pointer.

X26 Series

The X26 motors are dual-shaft analog clock motors. The model numbers are X26.101, X26.103, X26.123, X26.504. See the the “Switec Series Buyers Guide” in the Resources for more details.

X27 Series

The X27 motors are a new line replacing the X25 series. The X27 part numbers mirror the X25 series.

X12 Motor Drivers

The X12 part numbers refer to a series of driver chips developed by Switec. I have not been able to locate a supplier of these chips since microcomponents.ch shut down.

Suppliers

I have not found any well-know online store supplying these parts. They are however cheap and plentiful on ebay. However it can be difficult to determine exactly what you are getting; these motors are generally sold as Switec X25 replacements, without clearly specifying the manufacturer.

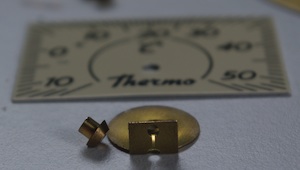

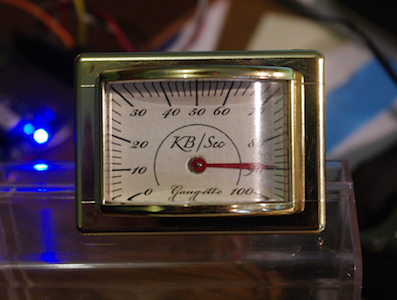

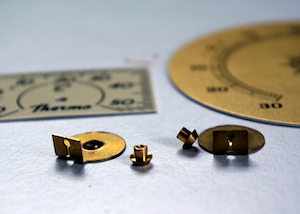

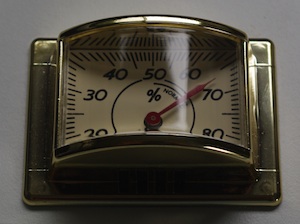

I used a Dremel to cut away the back panel giving access to the thermometer mechanism, but to my surprise the dial face was still firmly locked in place. After a bit of poking around I discovered that I could push the whole assembly out forward - in fact the plastic lens is only held in by friction, and the dial and mechanism are held in by the lens. No cutting was required. #LFMF

I used a Dremel to cut away the back panel giving access to the thermometer mechanism, but to my surprise the dial face was still firmly locked in place. After a bit of poking around I discovered that I could push the whole assembly out forward - in fact the plastic lens is only held in by friction, and the dial and mechanism are held in by the lens. No cutting was required. #LFMF